The WK vulcanizing press is designed for hot vulcanization of rubber conveyor belts, particularly those reinforced with fabric. This uniquely engineered system combines the proven advantages of traditional thermal vulcanizing technology while significantly reducing splicing time. Engineered with a compact and lightweight design, the WK-Press offers reduced energy consumption compared to conventional vulcanizing presses, providing a safe and cost-efficient solution for splicing conveyor belts with low to medium tensile strength.

Designed for greater efficiency, the WK vulcanizing press matches the performance of traditional hot splicing equipment while accelerating operations and reducing, energy consumption and shortening operational downtime. It is an ideal choice for operators seeking a streamlined solution that does not compromise on quality or control.

Suitable for splicing of single or multi-ply standard conveyor belts of low or medium strength class up to EP 1250/5 (according to DIN 22102) and rubber covers with polymer base:

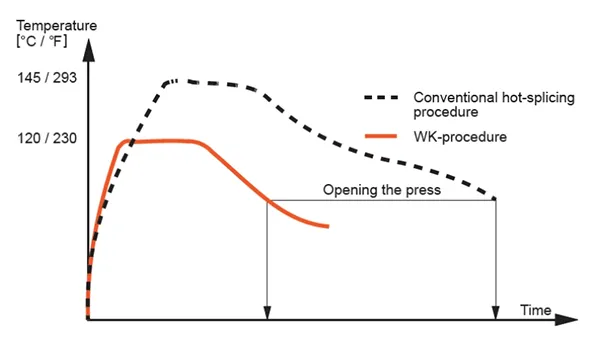

The diagram above shows the temperature curve over time when splicing an EP400/3 conveyor belt.

The short heating and cooling periods of the WK system are apparent when compared to the conventional vulcanization procedure.

| Model | Ref. No. | Heating Plate Size | Weight of Top Press Body | Weight of Bottom Press Body | Power/Wattage | Power Supply |

| TW-Press 600 | 565 3007 | 660×330mm | 42kg | 58kg | 2×1.0kW | 230V-50Hz |

| TW-Press 800 | 565 3107 | 815×330mm | 48kg | 65kg | 2×1.2kW | 230V-50Hz |

| TW-Press 900 | 565 3117 | 915×350mm 915×400mm |

53kg | 79kg | 2×1.5kW | 230V-50Hz |

| TW-Press 1000 | 565 3127 | 1015×350mm 1015×400mm |

58kg | 79kg | 2×1.85kW | 230V-50Hz |

| TW-Press 1000 | 565 3137 | 1115×470mm 1115×350mm |

65kg | 78kg | 2×2.4kW | 230V-50Hz |

| TW-Press 1200 | 565 3147 | 1350×470mm 1320×350mm |

85kg | 100kg | 2×3.2kW | 415V-50Hz |

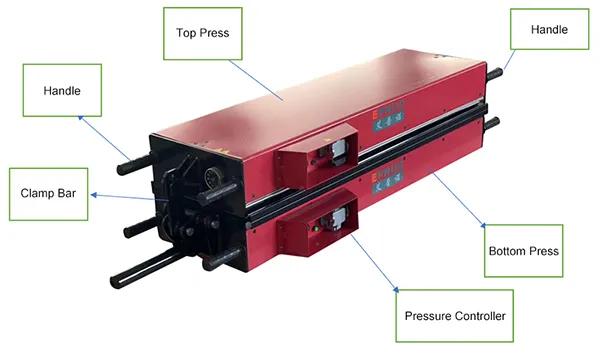

Begin by inspecting the performance of all key components, including the heating system, pressure system, and control unit. Set the appropriate temperature and pressure parameters according to your vulcanization requirements. Conduct a no-load trial run to ensure stable operation and check for any abnormal noise or vibration.

The WK vulcanizing presses are compact, lightweight, and easy to operate and transport, making them suitable for field use and quick deployment.

We’re here to help with expert advice and prompt support with efficient solutions.