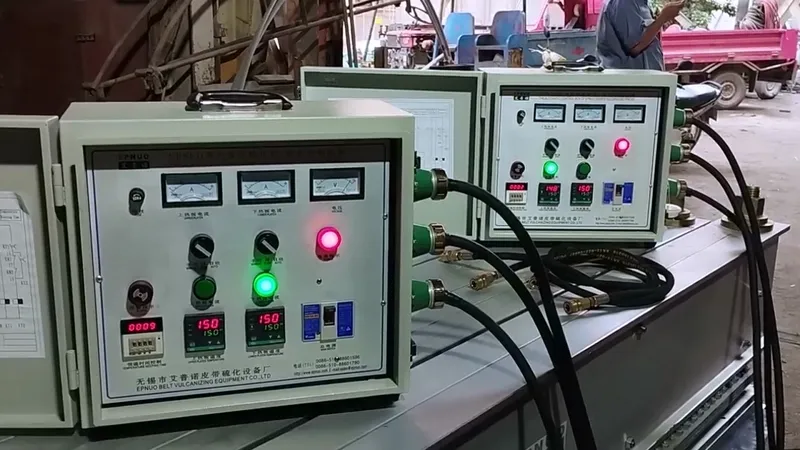

The water-cooled vulcanizing press is engineered for speed, portability, and high-performance splicing. Constructed from lightweight aluminum alloy, it features a compact design and quick assembly, making it the ideal solution for rubber conveyor belt jointing on-site.

This is a heavy-duty sectional vulcanizer widely recognized in the industry for its durability, lightweight build, and suitability for use in harsh mining environments. Designed for full splicing coverage, whether fabric belts or steel cord belts, it supports both single-unit and multi-unit configurations based on belt length. Compatible with a variety of splice shapes, including skive, rectangular, and chevron joints, the vulcanizer offers a major advantage with its rapid cooling system.

Unlike traditional vulcanizers that take 4-5 hours to cool naturally, this vulcanizing press cools to below 70°C within just 15-20 minutes, significantly reducing repair time and allowing faster return to operation. This makes it especially valuable for field repairs or projects involving dozens or even hundreds of splices, where every minute saved is a major production gain.

The conveyer belt vulcanizing presses are widely used across bulk material handling systems in industries such as metallurgy, mining, power generation, ports, building materials, and chemical processing. They are designed for splicing and repairing a variety of conveyor belts, including EP (polyester-nylon) belts, nylon conveyor belts, cotton canvas belts and conveyor belts with steel cable cores.

| Model | Max. Belt Width |

Platen Size | Splice Length (Minus 2in/50mm For Finger Splice) |

Traverse Bar System | Main Component Weight | Approx. Total Weight |

||||||||||||||

| A | B | C | Number Of Traverse Bars |

Type | Bar Length | Traverse Bar | Platen | |||||||||||||

| in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | lbs | kg | lbs | kg | lbs | kg | |||

| EPN-1930-22-100-E4P-2EA42 | 24 | 610 | 19 | 480 | 30 | 760 | 28 | 710 | 13 | 330 | 2 | EA | 42 | 1067 | 52 | 24 | 55 | 25 | 501 | 228 |

| EPN-1937-22-100-E4P-2EA49 | 30 | 760 | 19 | 480 | 37 | 940 | 34 | 865 | 13 | 330 | 2 | EA | 49 | 1245 | 61 | 28 | 68 | 31 | 568 | 258 |

| EPN-1943-22-100-E4P-2EA55 | 36 | 915 | 19 | 480 | 43 | 1090 | 40 | 1015 | 13 | 330 | 2 | EA | 55 | 1397 | 68 | 31 | 79 | 36 | 624 | 284 |

| EPN-2843-22-100-E4P-3EA55 | 36 | 915 | 28 | 710 | 43 | 1090 | 40 | 1015 | 22 | 560 | 3 | EA | 55 | 1397 | 68 | 31 | 116 | 53 | 917 | 417 |

| EPN-3343-22-100-E4P-4EA55 | 36 | 915 | 33 | 840 | 43 | 1090 | 40 | 1015 | 27 | 685 | 4 | EA | 55 | 1397 | 68 | 31 | 137 | 62 | 1151 | 523 |

| EPN-3743-22-100-E4P-4EA55 | 36 | 915 | 37 | 940 | 43 | 1090 | 40 | 1015 | 31 | 785 | 4 | EA | 55 | 1397 | 68 | 31 | 153 | 70 | 1199 | 545 |

| EPN-1950-22-100-E4P-2EA62 | 42 | 1065 | 19 | 480 | 50 | 1270 | 46 | 1170 | 13 | 330 | 2 | EA | 62 | 1575 | 77 | 35 | 92 | 42 | 691 | 314 |

| EPN-2850-22-100-E4P-3EA62 | 42 | 1065 | 28 | 710 | 50 | 1270 | 46 | 1170 | 22 | 560 | 3 | EA | 62 | 1575 | 77 | 35 | 135 | 61 | 1015 | 462 |

| EPN-3350-22-100-E4P-4EA62 | 42 | 1065 | 33 | 840 | 50 | 1270 | 46 | 1170 | 27 | 685 | 4 | EA | 62 | 1575 | 77 | 35 | 159 | 72 | 1275 | 580 |

| EPN-3750-22-100-E4P-4EA62 | 42 | 1065 | 37 | 940 | 50 | 1270 | 46 | 1170 | 31 | 785 | 4 | EA | 62 | 1575 | 77 | 35 | 178 | 81 | 1330 | 604 |

| EPN-4350-22-100-E4P-5EA62 | 42 | 1065 | 43 | 1090 | 50 | 1270 | 46 | 1170 | 37 | 940 | 5 | EA | 62 | 1575 | 77 | 35 | 207 | 94 | 1603 | 729 |

| EPN-1958-22-100-E4P-2EA70 | 48 | 1220 | 19 | 480 | 58 | 1475 | 54 | 1370 | 13 | 330 | 2 | EA | 70 | 1778 | 87 | 40 | 106 | 48 | 766 | 348 |

| EPN-2858-22-100-E4P-3EA70 | 48 | 1220 | 28 | 710 | 58 | 1475 | 54 | 1370 | 22 | 560 | 3 | EA | 70 | 1778 | 87 | 40 | 157 | 71 | 1128 | 513 |

| EPN-3358-22-100-E4P-4EA70 | 48 | 1220 | 33 | 840 | 58 | 1475 | 54 | 1370 | 27 | 685 | 4 | EA | 70 | 1778 | 87 | 40 | 185 | 84 | 1417 | 644 |

| EPN-3758-22-100-E4P-4EA70 | 48 | 1220 | 37 | 940 | 58 | 1475 | 54 | 1370 | 31 | 785 | 4 | EA | 70 | 1778 | 87 | 40 | 207 | 94 | 1479 | 672 |

| EPN-4358-22-100-E4P-5EA70 | 48 | 1220 | 43 | 1090 | 58 | 1475 | 54 | 1370 | 37 | 940 | 5 | EA | 70 | 1778 | 87 | 40 | 240 | 109 | 1784 | 811 |

| EPN-1965-22-100-E4P-2EA77 | 54 | 1370 | 19 | 480 | 65 | 1650 | 60 | 1525 | 13 | 330 | 2 | EA | 77 | 1956 | 95 | 44 | 119 | 54 | 833 | 378 |

| EPN-2865-22-100-E4P-3EA77 | 54 | 1370 | 28 | 710 | 65 | 1650 | 60 | 1525 | 22 | 560 | 3 | EA | 77 | 1956 | 95 | 44 | 175 | 80 | 1227 | 558 |

| EPN-3365-22-100-E4P-4EA77 | 54 | 1370 | 33 | 840 | 65 | 1650 | 60 | 1525 | 27 | 685 | 4 | EA | 77 | 1956 | 95 | 44 | 207 | 94 | 1541 | 701 |

| EPN-3765-22-100-E4P-4EA77 | 54 | 1370 | 37 | 940 | 65 | 1650 | 60 | 1525 | 31 | 785 | 4 | EA | 77 | 1956 | 95 | 44 | 232 | 105 | 1610 | 732 |

| EPN-4365-22-100-E4P-5EA77 | 54 | 1370 | 43 | 1090 | 65 | 1650 | 60 | 1525 | 37 | 940 | 5 | EA | 77 | 1956 | 95 | 44 | 270 | 123 | 1942 | 883 |

| EPN-1971-22-100-E4P-2EAX83 | 60 | 1525 | 19 | 480 | 71 | 1800 | 66 | 1675 | 13 | 330 | 2 | EAX | 83 | 2108 | 126 | 58 | 130 | 59 | 990 | 450 |

| EPN-2871-22-100-E4P-3EAX83 | 60 | 1525 | 28 | 710 | 71 | 1800 | 66 | 1675 | 22 | 560 | 3 | EAX | 83 | 2108 | 126 | 58 | 192 | 87 | 1462 | 665 |

| EPN-3371-22-100-E4P-4EAX83 | 60 | 1525 | 33 | 840 | 71 | 1800 | 66 | 1675 | 27 | 685 | 4 | EAX | 83 | 2108 | 126 | 58 | 226 | 103 | 1850 | 841 |

| EPN-3771-22-100-E4P-4EAX83 | 60 | 1525 | 37 | 940 | 71 | 1800 | 66 | 1675 | 31 | 785 | 4 | EAX | 83 | 2108 | 126 | 58 | 253 | 115 | 1924 | 875 |

| EPN-4371-22-100-E4P-5EAX83 | 60 | 1525 | 43 | 1090 | 71 | 1800 | 66 | 1675 | 37 | 940 | 5 | EAX | 83 | 2108 | 126 | 58 | 294 | 134 | 2330 | 1059 |

| EPN-1984-22-100-E4P-2EAX96 | 72 | 1830 | 19 | 480 | 84 | 2135 | 78 | 1980 | 13 | 330 | 2 | EAX | 96 | 2438 | 146 | 67 | 154 | 70 | 1128 | 513 |

| EPN-2884-22-100-E4P-3EAX96 | 72 | 1830 | 28 | 710 | 84 | 2135 | 78 | 1980 | 22 | 560 | 3 | EAX | 96 | 2438 | 146 | 67 | 227 | 103 | 1667 | 758 |

| EPN-3384-22-100-E4P-4EAX96 | 72 | 1830 | 33 | 840 | 84 | 2135 | 78 | 1980 | 27 | 685 | 4 | EAX | 96 | 2438 | 146 | 67 | 267 | 121 | 2110 | 959 |

| EPN-3784-22-100-E4P-4EAX96 | 72 | 1830 | 37 | 940 | 84 | 2135 | 78 | 1980 | 31 | 785 | 4 | EAX | 96 | 2438 | 146 | 67 | 300 | 136 | 2196 | 998 |

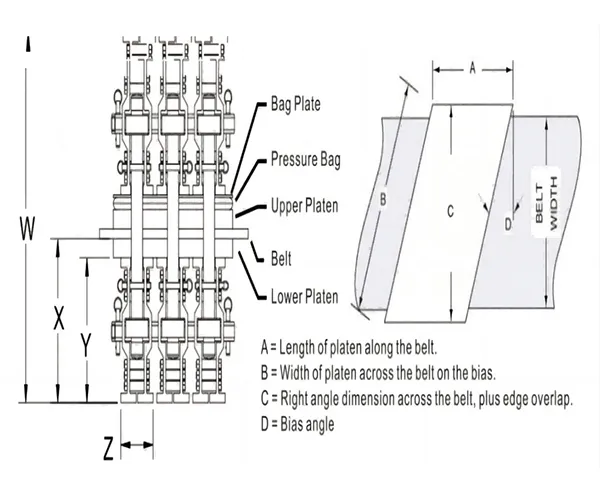

| Type | W | X | Y | Z | |

| EA | in | 22 | 9.75 | 7.75 | 7 |

| mm | 559 | 248 | 197 | 178 | |

| EAX | in | 27.5 | 12.5 | 10.5 | 7 |

| mm | 699 | 318 | 267 | 178 | |

| EB | in | 32.5 | 15 | 13 | 6 |

| mm | 826 | 381 | 330 | 152 | |

| EC | in | 32.5 | 15 | 13 | 6.5 |

| mm | 826 | 381 | 330 | 165 | |

| E380 | in | 36.5 | 17 | 15 | 6.5 |

| mm | 927 | 432 | 381 | 165 | |

| E4390 | in | 40.5 | 19 | 17 | 6.5 |

| mm | 1029 | 483 | 432 | 165 | |

Models can be customized upon request to meet specific requirements, including custom dimensions, rectangular configurations, various platen arrangements, or higher working pressure ratings. For more information, please contact us or your local EPNUO representative.

Yes, but it’s essential to ensure the vulcanizer matches the belt material, whether fabric, steel cord, or rubber, as well as the required temperature, pressure, and platen size for effective splicing.

Conveyor belt vulcanizers are widely used in mining, metallurgy, coal, cement, chemical processing, and other bulk material handling industries.

For example, in coal mines, vulcanizers are used to repair and join belts transporting coal. In cement plants, they help maintain conveyor systems critical to the production line.

Vulcanizing temperature and duration depend primarily on the belt material and thickness. For standard rubber conveyor belts, the typical vulcanizing temperature ranges between 140°C and 150°C. As a general rule, allow approximately 4 minutes per millimeter of belt thickness to ensure proper curing.

We’re here to help with expert advice and prompt support with efficient solutions.